Cavity walls are a common construction feature in many homes, offering insulation and structural benefits. However, over time, these walls may need strengthening to maintain their integrity and efficiency. One effective method is foam injection, known in Chinese as “加强空斗墙 注入泡沫”.

In this guide, we will explore everything about strengthening cavity walls with foam injection, including its benefits, process, materials, risks, and frequently asked questions. This comprehensive approach ensures a thorough understanding for homeowners looking to improve their property’s durability and energy efficiency.

What is a Cavity Wall?

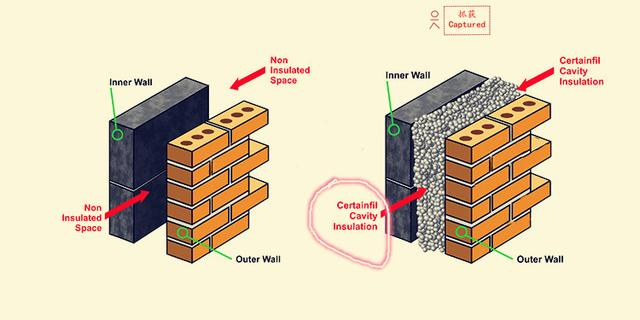

A cavity wall consists of two layers (or “leaves”) of masonry, separated by a gap (cavity). This design was developed to prevent moisture from penetrating a building’s interior while enhancing insulation. The inner leaf is typically the load-bearing wall, while the outer leaf serves as a protective shield against external weather conditions.

Features of Cavity Walls

- Thermal Insulation: The gap reduces heat transfer, keeping indoor temperatures stable.

- Moisture Prevention: The cavity prevents rainwater from reaching the inner walls, reducing dampness and mold.

- Soundproofing: The air gap and insulation materials can reduce noise pollution from outside sources.

- Energy Efficiency: A well-insulated cavity wall lowers heating and cooling costs.

Over time, however, cavity walls may develop issues that necessitate additional reinforcement, such as foam injection.

Why Strengthen Cavity Walls?

Although cavity walls are designed to be durable, several factors can weaken them, making reinforcement necessary.

Also Read: Traceloans: A Comprehensive Guide

Common Problems in Cavity Walls

- Structural Weakness: Due to age, poor construction, or external forces, the cavity walls may lose stability.

- Energy Loss: If the cavity is not properly insulated, it can lead to significant heat loss and higher energy bills.

- Moisture Penetration: Cracks and voids in the cavity can allow moisture infiltration, causing mold growth and internal damage.

- Thermal Bridging: Some parts of the cavity may transfer heat more efficiently than others, leading to uneven temperature control.

Foam injection is an ideal solution to address these concerns by filling voids and strengthening the entire structure.

What is Foam Injection? (加强空斗墙 注入泡沫)

Foam injection involves filling the cavity space between the inner and outer layers of a wall with an expanding foam material. This process improves the wall’s insulation, durability, and resistance to moisture penetration.

Types of Foam Used for Injection

- Polyurethane Foam (PU Foam) – Offers excellent thermal insulation and structural support.

- Phenolic Foam – A fire-resistant option that provides high thermal efficiency.

- Polystyrene Bead Foam – Lightweight and breathable, ideal for older buildings.

Each type of foam has its advantages, and choosing the right one depends on factors such as building material, climate, and budget.

Also Read: ShortEngine.com: The Ultimate Platform for Short-Form Content Creation

The Process of Foam Injection (加强空斗墙 注入泡沫)

To ensure a successful application, foam injection follows a structured process:

Step 1: Inspection and Assessment

- A professional inspects the cavity walls using a borescope to check for gaps, cracks, and existing insulation.

- Moisture levels are tested to ensure foam compatibility.

- A structural analysis determines whether additional repairs are needed before foam application.

Step 2: Preparation

- Small holes are drilled into the outer wall at specific intervals to allow foam insertion.

- Any loose debris or old insulation is removed if necessary.

Step 3: Foam Injection

- A specialized machine injects liquid foam into the cavity, where it expands and hardens.

- The foam spreads evenly, filling gaps and voids to reinforce the structure.

Step 4: Sealing and Finishing

- Once the foam sets, the drilled holes are sealed with matching mortar or cement.

- A final inspection ensures complete coverage and proper insulation.

Step 5: Quality Check and Maintenance Guidance

- The homeowner receives guidance on monitoring their walls for any potential issues.

- Regular inspections are recommended to maintain structural integrity.

Benefits of Foam Injection in Cavity Walls

1. Enhanced Structural Integrity

- Foam injection increases the wall’s strength, reducing the risk of collapse or cracks.

- The bonding effect between layers adds durability to the entire structure.

2. Improved Thermal Insulation

- Filling the cavity with foam reduces heat loss by up to 70%.

- Ensures energy efficiency by keeping homes warmer in winter and cooler in summer.

3. Moisture Resistance

- Foam prevents water from seeping through the walls, reducing mold and mildew formation.

- Ideal for rain-prone areas where moisture infiltration is a concern.

4. Noise Reduction

- Foam absorbs sound vibrations, minimizing external noise pollution.

- Ideal for homes near highways, airports, or busy streets.

5. Cost-Effective in the Long Run

- Lower energy bills due to improved insulation.

- Reduced maintenance costs by preventing structural damage.

Potential Risks and Precautions

Although foam injection has many benefits, there are some risks to consider:

Also Read: Cyanová: Everything You Need to Know About This Unique Shade

1. Improper Installation Can Cause Issues

- Poorly injected foam may leave gaps, reducing insulation effectiveness.

- Overfilling the cavity can create pressure on the walls, causing cracks.

2. Moisture Trapping

- If walls already have moisture problems, foam can trap water inside, leading to dampness and decay.

- Pre-installation moisture testing is crucial to prevent this.

3. Potential for Material Degradation

- Some low-quality foams may shrink or break down over time.

- Using high-quality foam from trusted suppliers prevents this issue.

Frequently Asked Questions (FAQs)

Is foam injection suitable for all homes?

Not all buildings are compatible with foam injection. Older homes with very narrow cavities may not be suitable.

How long does the foam last?

High-quality injected foam can last for 20-30 years with minimal maintenance.

Can I do foam injection myself?

No, foam injection requires specialized equipment and expertise to ensure proper application.

Does foam injection affect property value?

Yes, well-insulated homes often have higher resale values due to energy efficiency and durability.

Will my walls look different after foam injection?

No major changes occur. Drilled holes are sealed with matching mortar, making them virtually invisible.

Can foam injection fix an already damp wall?

No, existing moisture issues should be resolved before foam injection to avoid trapping water inside the cavity.

How much does foam injection cost?

Costs vary based on wall size, foam type, and labor. On average, it ranges from $1,500 to $5,000.

Is foam injection environmentally friendly?

Some foams are eco-friendly, but it’s important to choose low-VOC and non-toxic materials.

How long does the process take?

Typically, 1-3 days, depending on the size of the project.

What should I do before getting foam injection?

Hire a professional to inspect your walls for moisture, damage, or obstructions.

Conclusion

Foam injection (加强空斗墙 注入泡沫) is an excellent solution for reinforcing cavity walls, improving insulation, structural integrity, and moisture resistance. However, proper assessment and professional installation are key to ensuring long-lasting benefits. If you’re considering this method, consult an expert to determine whether your walls are suitable and select the best type of foam for your home.